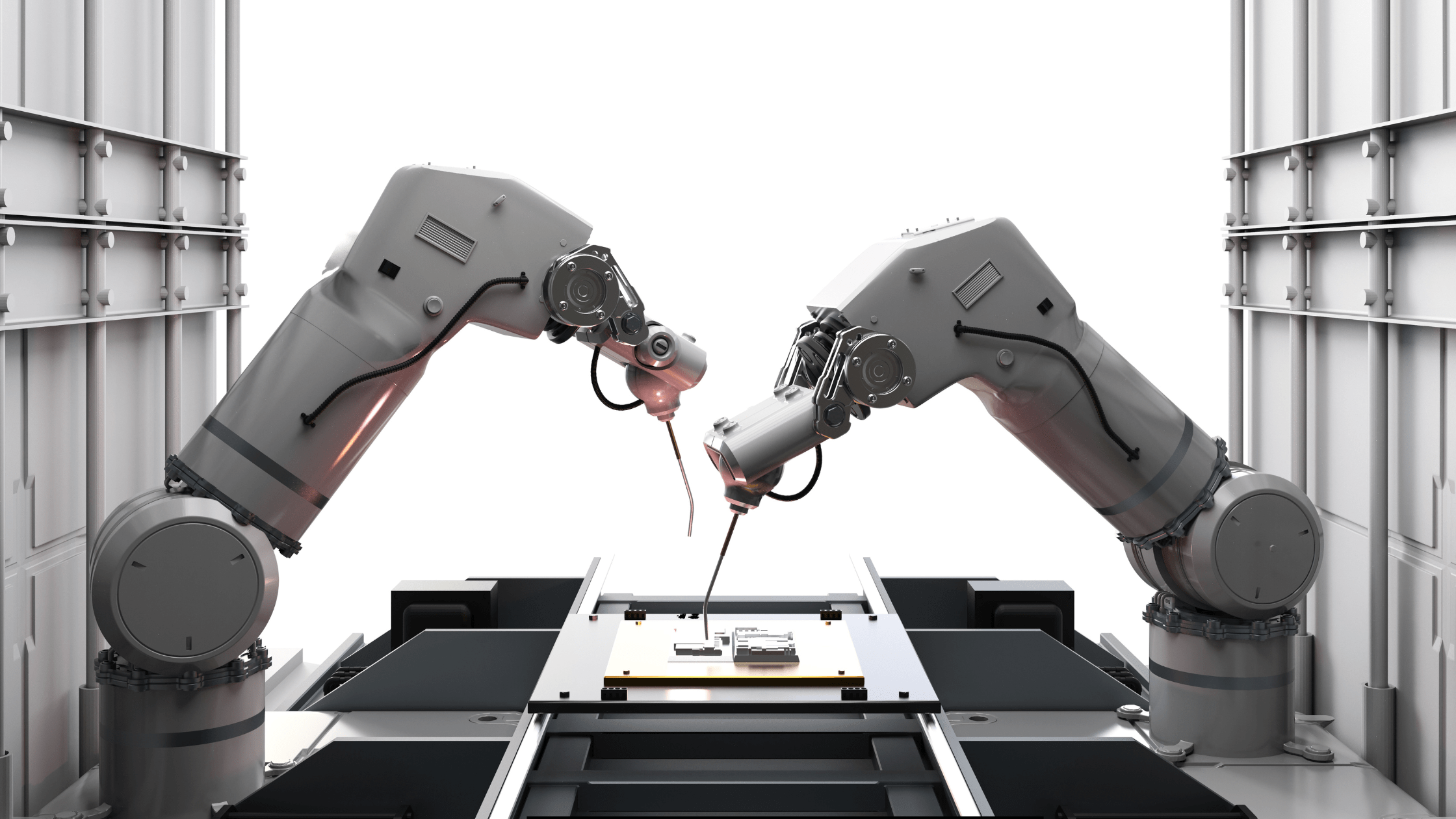

In the ever-evolving landscape of manufacturing, precision and innovation are paramount. For 416 Automation Inc., these principles drive the creation of end-of-line testing solutions that automate tasks traditionally performed by humans. By focusing on practical, real-world applications, 416 Automation is revolutionizing quality assurance in the automotive industry.

Experience and Innovation in Built-to-Order Solutions

With 15 years of experience in providing built-to-order automated testing solutions for the automotive industry, 416 Automation has established itself as a leader in the field. Our commitment to integrating new technologies into our systems and designs ensures that we remain at the forefront of industry advancements, continually improving the quality and efficiency of our solutions.

Established companies bring a wealth of expertise, ensuring rigorous testing and compliance with global standards, which is crucial for accessing global markets and enhancing product safety and reliability. This expertise helps in minimizing the chances of human error and optimizing the testing process to achieve near-zero defect rates.

Why Experience Matters

The importance of having experienced professionals in building automated testing solutions cannot be overstated. As highlighted in a McKinsey article on mastering automotive software excellence, the complexity of modern automotive systems requires deep expertise to ensure both safety and functionality. The article emphasizes that the shift towards software-driven vehicles necessitates rigorous testing and validation to meet high safety standards and performance expectations. This underscores the value of working with seasoned companies like 416 Automation, who possess the technical know-how and industry experience to deliver reliable and innovative solutions.

Real-World Applications of Automation

At 416 Automation, the automation of end-of-line testing is about solving everyday challenges faced by manufacturers. Here are some key examples of how our solutions are making a difference:

- Auto Connect System: Traditionally, a person had to connect the seat to the tester using a cable. With our auto connect solution, this task is now automated, increasing efficiency and reducing the potential for human error. Learn more about our Auto Connect System.

- SeatBot: Previously, testing seat functions such as track, recliner, cushion, lumbar, and leg extension required manual button presses. SeatBot automates this process using laser position sensors, ensuring all buttons work correctly and positioning the seat for the shipping robot.

- End-of-Line Tester (EOL): Our end-of-line testing solutions quickly measure airbags, pretensioners, heated and vented seats, entertainment systems, audio systems and much more to ensure all components are functioning correctly. Discover our End-of-Line Tester.

- Data Aggregation with Test Result Server (TRS): Many manufacturers collect data for compliance but miss opportunities for quality improvement. Our automated data aggregation solution saves engineers from tedious data analysis, allowing them to focus on driving production improvements. Explore our Test Result Server.

Encouraging Customer Engagement

416 Automation is committed to helping our customers identify and implement automation solutions tailored to their specific needs. We encourage manufacturers to contact us to explore how we can help automate their operations, improve quality, and increase efficiency.