In the relentless drive for excellence that defines modern manufacturing, ensuring product quality and reliability is paramount. Automated Test Equipment (ATE) stands at the heart of this pursuit, revolutionizing the critical end-of-line testing phase. Automated Test Equipment represents the pinnacle of innovation in manufacturing. These advanced systems autonomously perform a comprehensive range of tests on products to ensure compliance with stringent specifications. From electrical and functional assessments to thorough performance evaluations, ATE executes these tasks with minimal human intervention, significantly enhancing precision and efficiency.

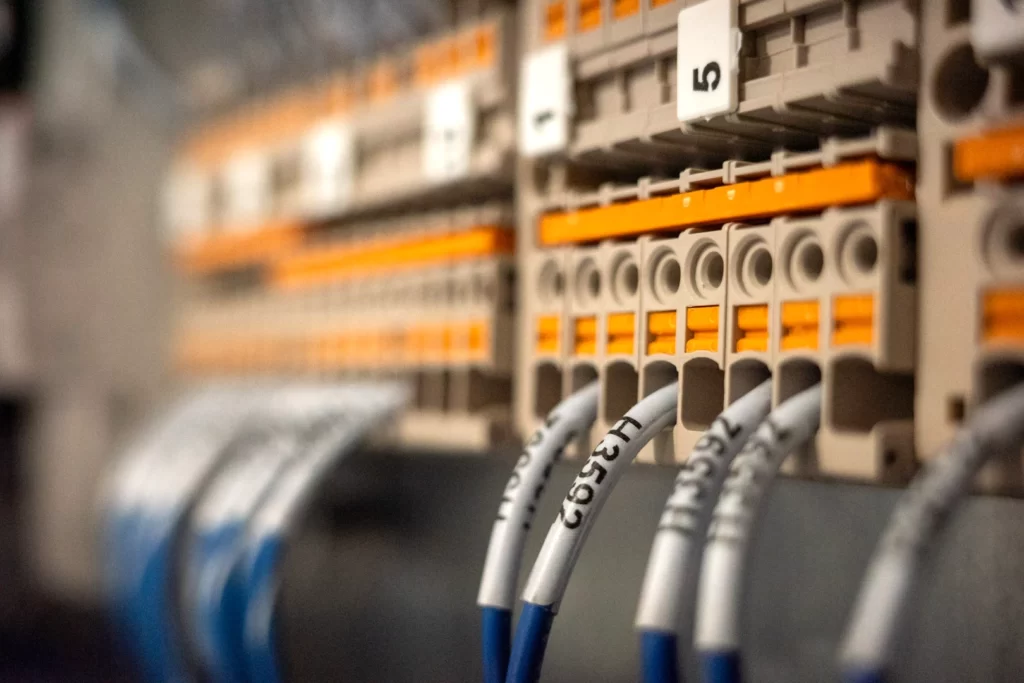

ATE systems are composed of several crucial components. Test instruments, such as oscilloscopes, multimeters, and signal generators, form the backbone of these systems, meticulously measuring and analyzing product parameters. Advanced software algorithms manage the testing process, facilitating seamless data collection and analysis. Custom-engineered fixtures securely position products during testing, ensuring consistent and accurate results. Additionally, state-of-the-art automated handlers and robots streamline the movement of products through various testing stages, optimizing workflow and reducing manual labor.

Benefits of Automated Test Equipment

The benefits of ATE are manifold. Increased throughput is a primary advantage, as these systems can test multiple products simultaneously, significantly accelerating the testing process and boosting productivity. By minimizing human involvement, ATE reduces the potential for error, ensuring more reliable and uniform test results. This automation of testing processes not only speeds up production but also reduces the need for manual labor, leading to substantial cost reductions. Furthermore, ATE systems are highly adaptable, capable of accommodating a wide variety of product types and sizes, making them ideal for diverse manufacturing requirements.

Applications of Automated Test Equipment

Automated Test Equipment is indispensable across numerous industries. In the automotive sector, ATE is vital for testing electronic control units (ECUs), sensors, and other critical components to ensure safety and performance. In consumer electronics, ATE ensures the functionality and quality of a wide range of devices, from smartphones and tablets to household gadgets. The medical device industry relies on ATE to verify the safety and efficacy of medical instruments, crucial for patient safety and regulatory compliance. Additionally, ATE assesses the reliability and performance of complex machinery components in industrial machinery, ensuring operational efficiency and longevity.

Technological advancements have further enhanced the capabilities of ATE. Machine vision, integrating cameras and sophisticated image processing software, enables precise visual inspections, detecting defects invisible to the naked eye. IoT connectivity enhances ATE systems with remote monitoring and data analysis capabilities, facilitating predictive maintenance and real-time decision-making. Moreover, AI-driven algorithms significantly improve defect detection accuracy and streamline the overall testing process, making it more efficient and reliable.

Challenges and Considerations

While ATE offers transformative benefits, it also presents certain challenges. The seamless incorporation of ATE systems into existing production lines can be complex and requires careful planning and execution. The upfront investment in ATE systems can be substantial; however, the long-term return on investment, through increased efficiency and reduced labor costs, often justifies the expenditure. Regular maintenance and precise calibration are essential to maintain the accuracy and functionality of ATE systems, ensuring they continue to perform optimally over a period of time.

Automated Test Equipment is revolutionizing the end-of-line testing landscape, offering unparalleled efficiency, accuracy, and scalability. As technological advancements continue to unfold, ATE systems are poised to evolve further, enhancing their capabilities and deepening their impact on the manufacturing industry. For manufacturers committed to excellence, investing in ATE is not just a strategic choice—it’s a game-changer that drives quality, reduces costs, and streamlines production processes. Embracing these advanced systems allows manufacturers to stay competitive in an ever-evolving market, ensuring that their products meet the highest standards of quality and performance, thereby fostering greater customer satisfaction and loyalty.